Customised hip resurfacing arthroplasty implant

CustomHip is a Greek project funded by the Special Secretariat for ERDF & CF Programmes (Operational Programme Competitiveness, Entrepreneurship and Innovation 2014-2020 (EPAnEK) - T2EDK-02410) aiming at the manufacturing of a pioneering Personalized Hip Resurfacing Implant with ceramic coating, automatically designed by an innovative software.

The purpose of CustomHip is to create an innovative metal hip arthroplasty implant (customized to the patient's needs) with a ceramic coating in order to avoid all the negative effects and disadvantages of friction between metal surfaces (metal on metal), while retaining all the advantages of the surface arthroplasty method, i.e., minimal bone removal of the femoral head.

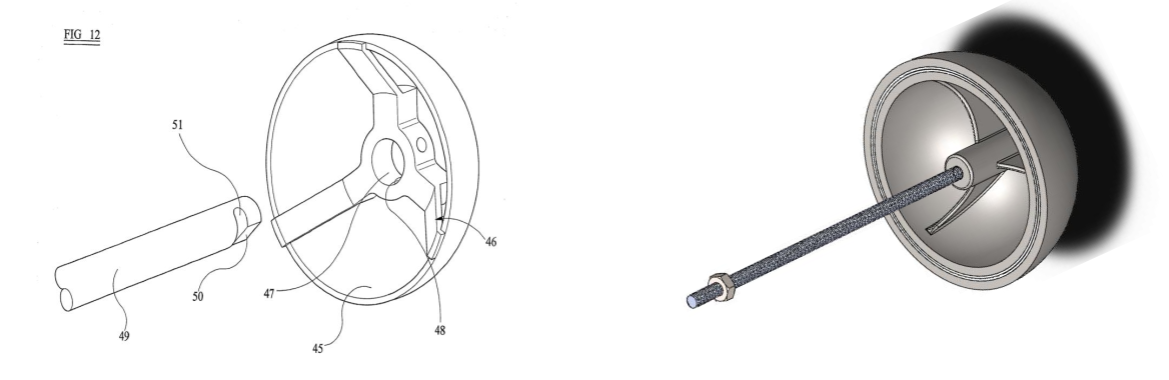

| A. The design and production of a resurfacing arthroplasty implant | The project aims at the development of an innovative surface arthroplasty implant consisting of a metal skeleton bearing a ceramic coating. |

| B. The development of an implant personalization software | The project aims at the development of an automated software for customized design and manufacturing of the resurfacing arthroplasty implant. |

| C. Dissimination | The aim of the dissemination and publicity activities is the promotion of the project and its potential benefits to stakeholders from industry, as well as to academic and research communities outside the consortium. |

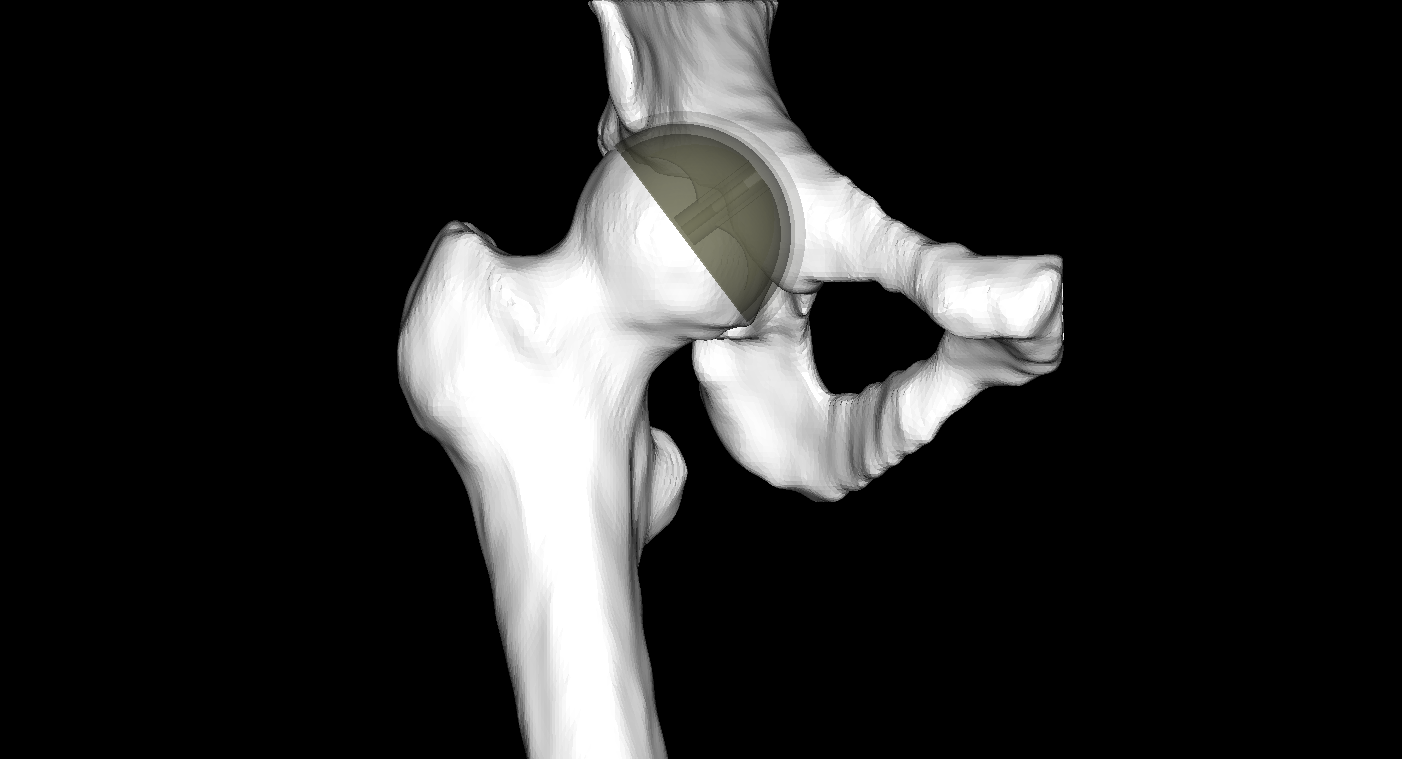

3D model of femoral bone, pelvis and personalized resurfacing arthroplasty implant

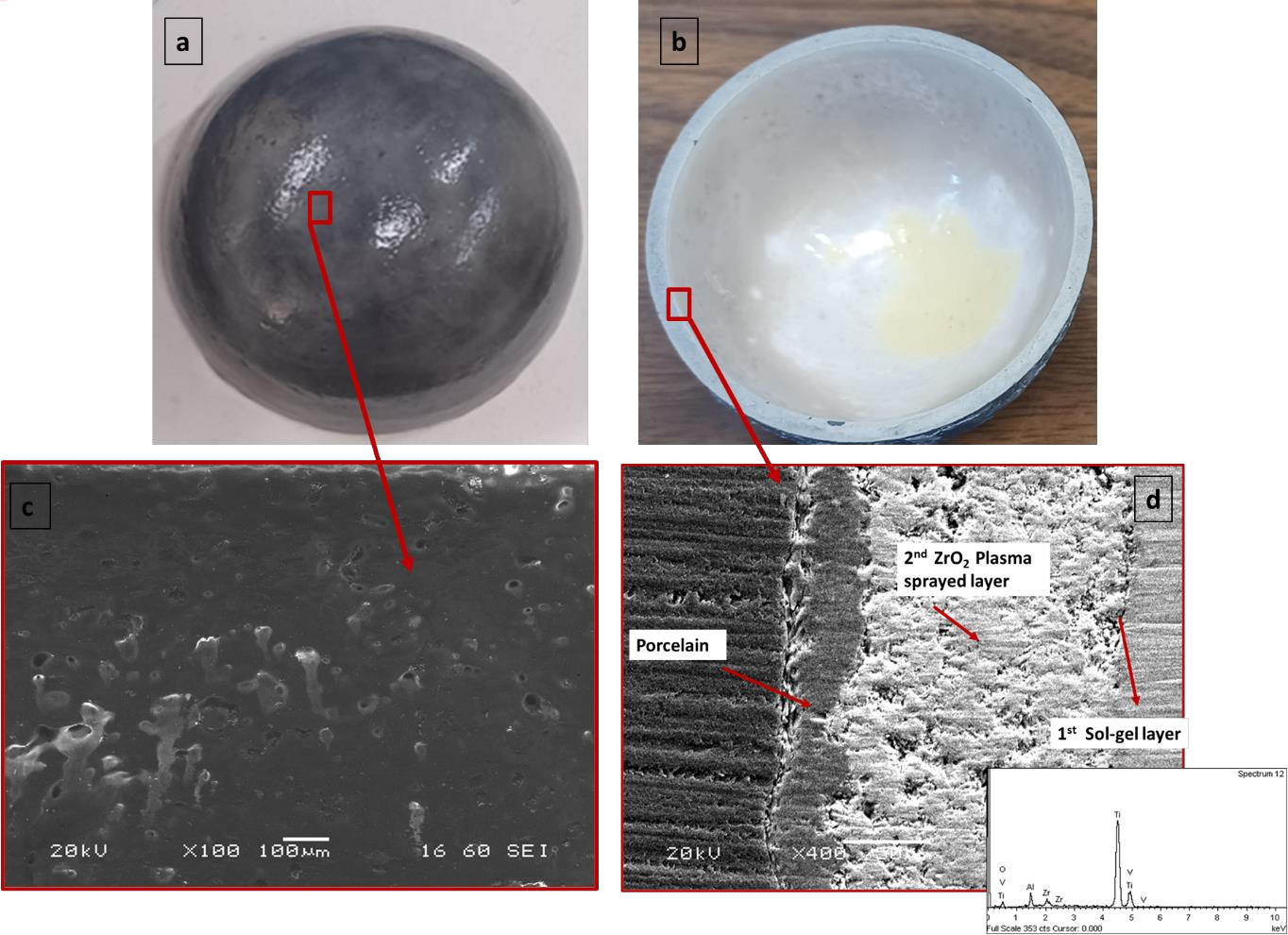

a, b) pictures of triple coated implants (sol – gel, thermal spray, porcelane), c) SEM images of the coated implant surface d) vertical cross section of the system of the three coating layers